Welcome to back to Year 2049! If you want to discover and keep up with trends, technologies, and innovations shaping the future without the jargon, subscribe for free below:

A new article will be sent to your inbox every Friday + you get to vote on the topics you want to learn about.

The $330,000 burger

Back in 2013, scientist Mark Post and food technician Peter Verstrate unveiled the first lab-grown burger. And it cost a cool $330,000 to make.

That burger marked the start of the race to create slaughter-free, tasty, and affordable meat.

Lab-grown meat, or cultivated meat, didn’t make it out of the lab until 2020. That was the year Singaporean regulators approved the sale of the first cultivated meat product: chicken nuggets made by SF-based Eat Just. And it was only available at a single members-only restaurant in Singapore.

Last month, the FDA gave the green light to UPSIDE Foods to sell their cultivated chicken (the company still needs to pass two inspections by the US Department of Agriculture before they can sell their chicken).

Over 100 companies are creating and developing cultivated meat and seafood, including beef, chicken, and salmon. In 2021, cultivated meat startups received over $1.9B in investments.

The problems lab-grown meat can solve

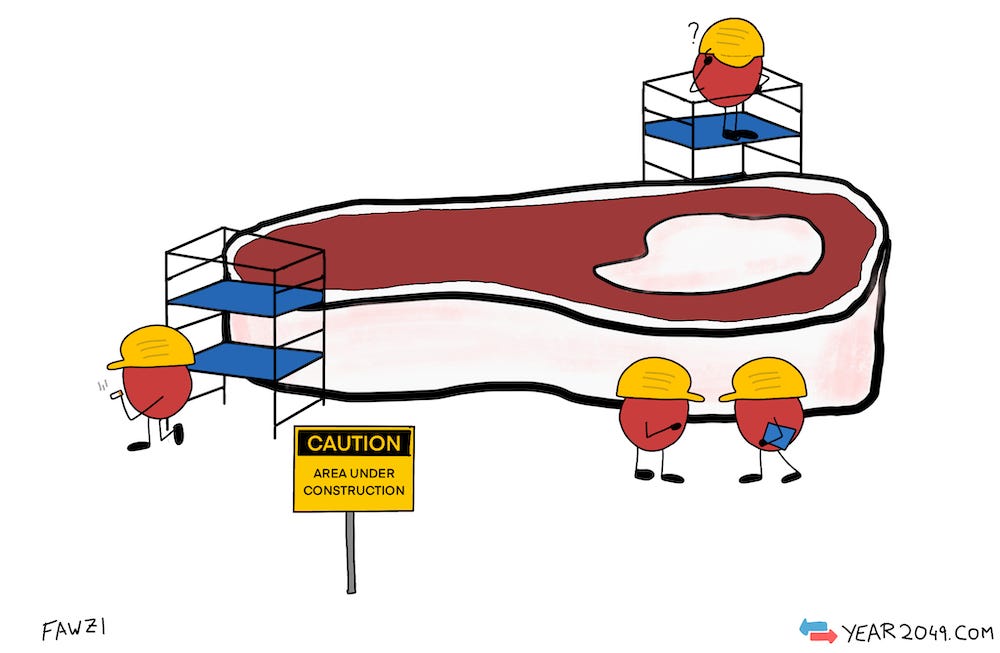

Comic: Cows and burgers. “Grass-fed” lies

Unlike traditional burgers and nuggets, cultivated meat is grown from animal cells rather than being the product of slaughtered animals. And if we can crack the code, it could address the severe problems of mass meat production:

Emissions:

Global livestock accounts for 14% of all man-made greenhouse gas emissions (UN FAO).

Cows and bulls are responsible for about 65% of livestock emissions.

Livestock is a significant emitter of methane, a greenhouse gas with 80 times the warming power of CO2 in its first 20 years in the atmosphere.

Deforestation: More agriculture and livestock leads to more deforestation, which removes valuable carbon sinks at a time when we desperately need them

Water usage: Meat production is a water-intensive process. It can take up to 2,400 gallons of water to produce one pound of beef. Lab-grown meat could cut that by 96%.

Human health: Factory farming is a hotbed for diseases that can transfer to humans. And the antibiotics fed to animals increase the risk of antimicrobial resistance.

Not only is cultivated meat less harmful to the environment, its ecosystems, and ourselves, but it promises to be a more humane way of eating meat.

This idea isn't new. Even Winston Churchill hinted at it almost a century ago:

“We shall escape the absurdity of growing a whole chicken to eat the breast or wing, by growing these parts separately under a suitable medium”

– Winston Churchill in 1931

How to grow meat in a lab

To understand the challenges of growing meat in a lab, here’s what you need to know about the process:

Stem cells are taken from animals → As a reminder, stem cells are versatile cells that can transform into almost any type of cell (blood cells, muscle cells, fat cells, etc.).

These cells are grown in a bioreactor to create meat → Cells grow in large steel tanks in a mix of nutrients, growth hormones, and fetal bovine serum.

The cells differentiate into specialty cells → By placing the cells in a "scaffolding" structure and varying the growth mixture, they start to differentiate into muscle, fat, and connective tissue cells.

The cells are harvested and processed into the desired meat → The entire process can take up to 8 weeks and additional processing depends on the type of meat we want to make.

The challenges of commercialization

The process isn't as easy as extracting cells and feeding them nutrients, because we're trying to replicate a process (and countless micro-processes) that occur naturally inside animals.

There are many challenges in making cultivated meat, but I want to focus on two:

The fetal bovine serum problem

The scaffolding problem

#1: The fetal bovine serum problem

Fetal bovine serum (FBS) is vital for growing meat in a bioreactor. It’s a cocktail of 1,800 proteins and 4,000 metabolites that help cells grow.

FBS is derived from the blood of cow fetuses and is a by-product of the beef industry. When a pregnant cow is headed for slaughter, the fetus is removed and its blood is drained. This is the ethical catch-22 of lab-grown meat: FBS is a must-have ingredient, but its availability depends on how many cows are slaughtered.

And FBS has a hefty price tag: 1L of FBS can cost up $1,500. Each cow fetus yields 150mL-550mL of FBS, and you need about 50L to make one beef burger.

Removing FBS from the lab-grown meat equation is one of the industry's biggest priorities, both from an ethical and financial standpoint.

#2: The structure problem

Joshua March, CEO of SciFi Foods, explains how replicating the structure of traditional meat is a challenge in his guest post on Noah Smith's

:"The output of this process is just a bunch of individual cells, essentially meat paste. While those cells can have the fats and proteins that create the flavour of meat, they don’t have any structure. Making a steak requires those cells to arrange together to form muscle fibres and other tissues that have 3D structure—a much more complex and resource-intensive process."

– Joshua March in

For that reason, animal cells need to be grown in a scaffold to help the cells grow and differentiate while delivering the necessary nutrients.

Joshua also explains why it's a complex and expensive process:

Animal cells will only attach to surfaces coated in specific proteins (like collagen)

Animal cells need a continuous supply of nutrients, growth factors, and oxygen. But these can't permeate deep into a 3D block of tissue. So the scaffold needs to have the equivalent of blood vessels to transport these nutrients to all the cells deep beneath the surface.

The up-and-coming solutions

The problems I mentioned are no reason to discount lab-grown meat.

The technology is still early, the benefits compared to traditional farming are clear, and its problems are opportunities for improvement and innovation.

Some companies and research groups are tackling these issues to bring lab-grown meat closer to our plates:

Magnets: A research group from the National University of Singapore may have found an alternative to FBS. The group exposed stem cells to magnetic fields, which released the molecules necessary for cells to develop into tissues.

Gene-editing: Joshua March's company, SciFi Foods, uses gene-editing to enable animal cells to grow at a larger scale outside an animal's body.

Animal-free alternatives to FBS: Mosa Meats, founded by the OG lab-grown burger makers Post and Verstrate, recently announced that they eliminated FBS from their cultivated meat production process. The company achieved cell differentiation without using FBS or genetically modifying cells, through a process known as serum starvation.

3D bioprinting: 3D printing using a bio-ink made from animal cells is another alternative. Last year, researchers in Japan showed off their 3D-printed Wagyu beef.

The blended approach: Companies like SciFi Foods and X blend both cultivated and plant-based meat. The former provides the flavour, and the latter gives it the texture.

I’ll be discussing these alternative solutions in more detail in upcoming posts.

Thanks for reading Year 2049! If you want to receive a new story each Friday, then subscribe and join our growing community of future-curious people:

Year 2049 is a free publication, and anyone can read this article for free.

Deep dive

If you enjoyed today’s story, I’ve compiled some additional links to satisfy your curiosity:

Launch of the world's first cultured meat hamburger in 2013 (YouTube)

A Lab-Grown-Meat Startup Gets the FDA’s Stamp of Approval (WIRED)

The science of cultivated meat (Good Food Institute) – highly recommended. They explain the science and challenges behind cultivated meat much better than I ever could.

The promise of cultivated meat on

– highly recommended. Joshua provides a great breakdown of cultivated meat’s value, an honest look at the challenges, and his thoughts on the future of the industry.

Gourmey grabs $48 million to keep working on lab-grown foie gras (TechCrunch)

Recommendation

Someone invented a language using ChatGPT

ChatGPT has taken over the social media feeds over the past week. The most interesting experiment I’ve found is

's. He used ChatGPT to invent a new language and wrote about it in his newsletter .Previous episodes you’ll enjoy

🍔 Can AI and a team of human chefs make plant-based food taste better?

🌾 The 3 approaches to vertical farming

You can also check out all previous Year 2049 articles to learn about other technologies and innovations shaping the future.

How would you rate this week's edition?

Congratulations Fawzi. Another great explainer post. Thank you.

I only had vague understanding of the subject up to now, but your explain a really lays it out very clearly and brings us up-to-date with developments.

This topic is vitally important, certainly not only for the sake of intriguing scientific development, but because of the impact on methane and everything else that goes with meat production

As one who freely admit to truly loving a great rare sirloin steak (preferably b-b-q’ed on the grill at the cottage with a glass of fine red vino in the other hand) and who thinks rather less of a nut cutlet, I am all for the direction that the industry is heading .

Moo moo

C

I’ve always struggled with this one. Like I get all the ways that lab grown meat is better than non lab grown meat, but it’s still meat. It seems like developing better plant-based proteins would be better health wise?

I am interested in cell cultured seafood though. Fish is actually really healthy, but because it has become tainted by mercury it has become much less so. Cell cultured seafood could solve for that, though I admit I still don’t really understand it!

(This is a great article about that btw!: https://www.growbyginkgo.com/2022/10/13/fish-out-of-water/)